For many businesses, forklifts are an essential piece of equipment at the warehouse or material handling location. As you know, your business’s equipment plays a crucial role in your investment. To receive a higher return on this investment, you must maintain your equipment. Your equipment can only increase efficiency and productivity if it’s in good condition.

Forklifts should receive preventive maintenance after every 250 to 300 hours of use to keep their parts moving and working as they should. It’s the key to ensuring your forklifts function correctly.

What Is the Importance of Regular Forklift Maintenance?

As equipment ages, its condition deteriorates — especially with daily use. Lift truck maintenance can slow this deterioration. Here are eight benefits of routine forklift maintenance service:

1. Improve Safety

In 2021, there were 70 worker forklift-related fatalities across all industries. While this is less than the number of fatalities in 2020, 70 fatalities are 70 too many. Routine maintenance can prevent accidents by noticing problems as soon as possible. You can’t prevent every accident, but you can improve conditions for your employees’ safety.

2. Maximize Service Life

It’s natural to want to protect your investments, especially when you invest a lot of money and time. Forklifts are a significant cost, so you must maintain them to get the most out of them.

When you tune up your equipment, you maximize its service life. Maintaining your equipment is the same as maintaining your car — if you change the oil regularly, it functions properly for longer. If you never change the oil, it will break down sooner.

3. Increase Productivity

If you consistently employ forklift repair services, you should consider preventive maintenance. When your team uses forklifts daily, their productivity will plummet if the equipment constantly needs lift truck repair services. Your team’s productivity will increase if your equipment is well-maintained and allows for smooth business operations.

4. Comply With Occupational Safety and Health Administration (OSHA) Standards

OSHA requires a daily inspection of all forklifts before use. If there is an accident, OSHA will inspect the equipment and request a service record to ensure you comply with their safety regulations. One of their safety regulations is to perform preventive maintenance based on the equipment manufacturer’s recommendations.

5. Avoid Expensive Repairs

Maintenance helps you avoid expensive repairs by addressing problems before they become significant. Repairing minor issues costs less than major issues. Additionally, when you fix minor problems as they arise, you prevent unexpected breakdowns. Unexpected breakdowns lead to emergency repairs and production shut-downs, which cost more than preventive maintenance.

6. Protect Your Investment

New equipment comes with a manufacturer’s warranty that protects your investment. Most of these warranties have stipulations regarding regular maintenance. As long as you maintain this schedule, you likely preserve your warranty, which can be useful if your equipment malfunctions.

7. Increase Resale Value

Eventually, you may wish to upgrade your equipment and may want to sell your old equipment when you do. Your old equipment’s resale value will increase if you regularly maintain it.

8. Plan Repairs

Service technicians can predict the life span of your forklift’s components. They can estimate when you might need to replace your equipment so you can prepare for the expense. Additionally, you can schedule repairs at your convenience instead of needing emergency repairs.

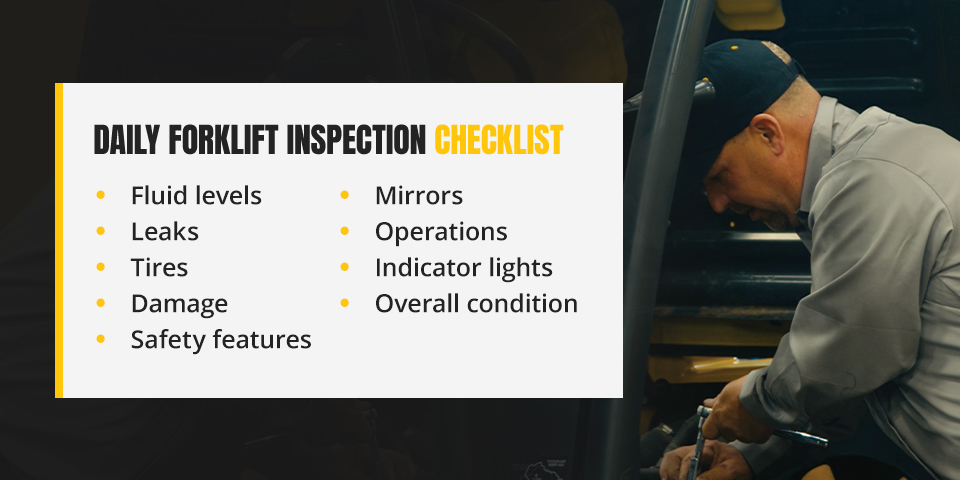

Daily Forklift Inspection Checklist

It’s crucial to perform a daily inspection before operating forklifts. Here’s what your team should check before using the lift trucks:

- Fluid levels: Check if you need to refill the oil, hydraulic fluid, water or coolant. These must be at the recommended level to prevent engine damage.

- Leaks: Walk around the machine and ensure the hoses are attached, and look for any defects or cracks. Glance under and around the forklift for pooling liquid. Use a stick or device to check the chain tension.

- Tires: Inspect the tires for cracks, signs of excessive wear and deflation. Use a gauge to read the pressure.

- Damage: Note any signs of damage that would interfere with operations, such as dents or protrusions.

- Safety features: Ensure all safety features, including the seatbelt, work correctly. See if the safety decals and nameplates are in place and legible. Check that the nameplate information matches the serial and model numbers and attachments.

- Mirrors: Check that you can see out of the mirrors and that they aren’t cracked or damaged.

- Operations: Perform a few test operations to see if the gears, levers, battery and steering wheel are operating correctly. Check the brakes, clutch and lights.

- Indicator lights: Address any indicator lights that are on before using the forklift.

- Overall condition: Examine the overall condition of the machine. Check the forks, including the top clip retaining pin and heel, the backrest extension and the finger guards. Notice if there are any loose or missing nuts, bolts or belts.

General Maintenance Tips

These general maintenance tips can assist your team in maintaining your equipment’s condition between the daily inspections:

- Instruct employees to check the forklift for damage after every collision, even minor ones.

- Create an inspection document so your team can check off the inspection areas and make notes.

- Only allow licensed operators and technicians to perform inspections.

- Instruct employees to clean their machines at the end of the work week.

- Instruct employees to report issues immediately so supervisors can schedule repairs to prevent breakdowns and significant damage.

- Have your employees flush the cooling system during warmer weather to remove deteriorated coolant.

Planned Maintenance

Planned maintenance, also known as preventive maintenance, is the only way to keep your forklifts and other equipment in good condition. It involves routine inspections, servicing and repairs so you can address potential and minor problems before they become significant. Addressing problems early ensures your forklifts continue to function properly and last as long as they should.

The benefits of planned maintenance include:

- Reduces downtime: Professionals identify and resolve minor issues before they lead to unexpected breakdowns or other costly disruptions.

- Extends life span: Planned maintenance prevents significant damage to your forklifts, ensuring they last for a long time.

- Maintains resale value: If you ever want or need to sell your equipment, you’ll get more buyers and a greater profit for keeping it in good condition.

- Increases safety: Since the inspections ensure the equipment operates as intended, they reduce the risk of accidents or malfunctions that could cause injuries.

You can work with a professional company to schedule planned maintenance. Burns offers flexible and customized maintenance plans tailored to your specific needs. We consider factors such as application, operating environment, lift truck make and model and your equipment’s age, usage and maintenance history to provide comprehensive maintenance services.

Our Periodic Maintenance (PM) Programs establish a regular service schedule to minimize downtime, enhance your fleet’s condition and boost productivity. By maintaining service records and providing quality parts for repairs, Burns aims to save you time and money by maximizing your facility’s uptime and keeping your equipment in excellent working condition.

Schedule Maintenance With Burns Industrial Equipment

Planned maintenance prevents you from worrying about your equipment’s safety and quality. When you create a maintenance schedule, you prevent breakdowns and decreased productivity and longevity, while optimizing your equipment’s safety, life span and performance.

You can partner with Burns Industrial Equipment to develop a custom maintenance schedule that keeps your equipment in excellent condition and maximizes your facility’s productivity. Our highly trained professionals can help keep your service records current while providing quality repair parts. If you experience an unexpected breakdown, we offer 24/7 emergency repair services. By partnering with experts like Burns, you can benefit from our expertise and ensure your equipment receives the attention and care it requires. View our forklift repair services and contact us today to create your custom maintenance plan and save time and money!