Pallet racking systems offer many advantages for warehouse operations. These solutions help your facility maximize efficiency and supercharge your daily operations, from streamlining inventory management practices to optimizing storage capacity. With various racks available and ever-changing warehousing needs, finding the ideal solution for your business is vital for reaping these benefits.

Let’s break down pallet racking types and the considerations for selecting the right option for your warehouse’s requirements.

Types of Industrial Pallet Racks

The ideal storage solutions for your operations will depend on a few factors, including:

- Space availability

- Storage requirements

- Inventory management practices

- Operational needs

Each racking system has advantages and considerations. Explore common types of warehouse racking solutions below.

- Cantilever rack: Racking with horizontal arms is excellent for storing long and bulky items, like pipes or sheet metal.

- Double-deep rack: These racks allow you to keep two pallets side by side, increasing storage density and requiring specialized forklifts.

- Drive-in rack: This system features continuous storage lanes with aisles that forklifts and other material handling equipment can drive directly into to retrieve or put away pallets.

- Drive-through rack: A drive-through racking solution is similar to a drive-in rack, but allows for equipment to enter one side and exit from another, boosting accessibility and first-in, first-out inventory management.

- Flow-through rack: These racks take advantage of gravity to transfer pallets from the loading to the unloading end using a gradual slope design.

- Pallet shuttle rack: These systems use semi-automated tools to move pallets around within the racking system. They reduce the need for equipment in the rack and are particularly well-suited for high-volume operations.

- Pick modules: This customized system incorporates features from different racks, picking stations and conveyor belts. They make order-picking processes more efficient.

- Push-back rack: With racking that supports last-in, first-out inventory management, workers load pallets from the front, pushing previous ones toward the back.

- Selective rack: As one of the most common pallet racking solutions, selective racks allow individual pallet access from different aisles for more flexible inventory management.

- Stack rack: These systems feature portable racks you can stack when you’re not using them. Many warehouses use them for storing temporary or seasonal inventory.

Benefits of Pallet Racking Systems

Pallet racking solutions can offer many benefits for warehouse operations. They can help your team enhance their daily processes with better organization, efficiency and accessibility.

Explore the advantages of warehouse racking systems below.

Optimizing Warehouse Use

Pallet racking systems optimize warehouses. They help you take advantage of vertical space and increase storage capacity, maximizing every square foot.

You can store more inventory and strategically use capacity with a more accessible layout that supports productivity.

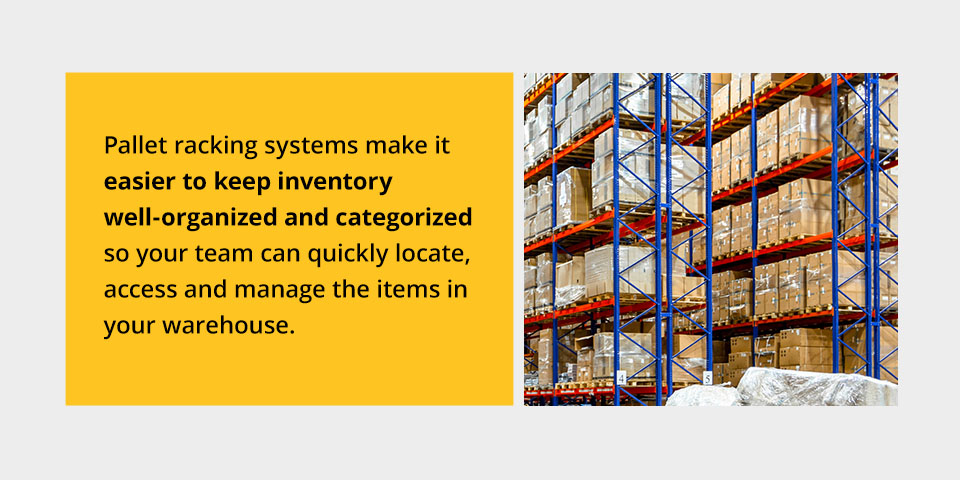

Streamlining Inventory Management

Another benefit of pallet racking solutions is enhancing your inventory management processes. These systems make it easier to keep inventory well-organized and categorized so your team can quickly locate, access and manage the items in your warehouse.

Pallet racking also allows warehouse equipment like forklifts and pallet jacks to maneuver quickly and safely. They can simplify your material handling processes by making your inventory more accessible.

These highly customizable systems allow you to tailor your storage solutions to your specific inventory management needs. Warehouse pallet racking offers more adaptability and flexibility with your changing storage requirements. You can reconfigure and modify your racking to accommodate your inventory as necessary.

Boosting Safety

Custom pallet racking solutions can enhance warehouse safety by providing secure storage systems designed specifically to withstand your items’ size and weight. Organized warehouses are also easier to maneuver around, increasing workplace safety.

Considerations for Warehouse Racking Solutions

Explore the following considerations to determine which warehouse solutions are ideal for your operation.

Warehouse Design and Layout

If you want to install pallet racking, remember your warehouse’s layout and design considerations. The floor space, ceiling height and any obstructions will influence the best system for your available space. You’ll want to select options that enable smooth, efficient material flow, which can ultimately boost your return on investment.

Load Capacity Requirements

Your inventory and other materials requiring storage are essential considerations for a pallet racking solution. You’ll need to determine your maximum load capacity to select a system that can accommodate your weight-bearing pallets.

Safety

Safety is a critical consideration for warehouse storage. Thoroughly explore your industry’s guidelines and regulations and select pallet racking systems that meet or exceed these criteria. From installation to ongoing maintenance, your business must ensure its storage solutions are always up to standard.

Training your team on best practices and how to safely approach warehouse storage operations is crucial for safeguarding your personnel and inventory.

Warehouse Management Systems and Processes

Your warehouse management systems are another critical consideration when selecting a racking solution. Choose storage that supports your daily processes and the software you use.

How you manage inventory control, orders and tracking will all influence which pallet racking solution makes the most sense with your business’ functions.

Inspections and Maintenance

Warehouse racking solutions require regular inspections to identify the following:

- Damage

- Loose components

- Signs of structural instability

Promptly addressing maintenance requirements is a best practice for keeping your storage systems operating at maximum capacity and preventing accidents. Your business should perform monthly visual inspections and fix anything that doesn’t work correctly. Have a professional inspect more closely as part of an annual inspection service.

Explore the Pallet Racking and Storage Solutions From Burns Industrial Equipment

Turn to Burns Industrial Equipment for advanced warehouse pallet racking and storage solutions. We can help you design your new warehouse or retrofit your existing one with custom racking systems to optimize your daily operations.

Our knowledgeable sales staff will guide you through the design, consulting, planning and installation process to ensure you get products tailored to your warehouse’s unique needs and requirements.

Are you ready to learn more? Browse pallet racking and storage solutions from Burns Industrial Equipment, then contact a specialist today!